Vinyl Acetate Monomer

Solventis is a trusted global supplier of Vinyl Acetate Monomer, serving customers across the UK, Europe and globally. With our offices in both the UK and Belgium, we are dedicated to providing a seamless service and offering competitive pricing on all our products. To discuss your specific requirements, get in touch with our expert team today.

What is Vinyl Acetate Monomer?

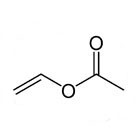

Vinyl Acetate Monomer (also known as acetic acid ethenyl ester, acetic acid ethylene ether, acetoxyethene, 1-acetoxyethylene, ethenyl ethanoate, ethenyl acetate, and acetic acid vinyl ester) is a colourless mobile liquid with a pungent odour. It has the formula CH3COOCH=CH2 and is a key raw material in the production of chemicals which are then used to manufacture a wide variety of consumer and industrial products.

How is it produced?

The main production method for vinyl acetate monomer is the reaction of ethylene and acetic acid with oxygen, in the presence of a palladium catalyst. The VAM is recovered by condensation and scrubbing and is then purified by distillation. A new manufacturing process, dubbed Leap, could offer large capital cost savings as a more efficient fluidised bed system replaces the fixed bed reactors currently in use.

The oldest means of manufacturing VAM is the addition of acetic acid to acetylene and this process is still used but not on a large scale.

How is it stored and distributed?

Vinyl acetate monomer is stored in mild steel storage tanks and/or new or reconditioned steel drums and can be transported by bulk vessels or tank trucks. It has a specific gravity of 0.933 and a flash point of -8° C (closed cup) and is highly flammable. It should therefore be stored in a cool, dry, well-ventilated area that is free from the risk of ignition. For transportation purposes, it is classified as packing group II and hazard class 3 and it is an irritant.

What is it used for?

Vinyl acetate monomer is mainly used in the production of polyvinyl acetate (PVAc) and polyvinyl alcohol (PVOH or PVA). In fact, 80 % of all the VAM produced in the world is used to make these two chemicals. Polyvinyl acetate is used in paints, adhesives, paper coatings and textile treatments, while polyvinyl alcohol is used in the production of adhesives, coatings, and water soluble packaging, and textile warp sizing.

VAM is also used to make polyvinyl butyral (PVB) which is used in laminated safety glass for cars and buildings. Ethylene-vinyl acetate (EVA) resin is also made from VAM and is used in the manufacture of packaging film, heavy-duty bags, extrusion coating, wire and cable jacketing, hot-melt adhesives and cross-linked foam. Other products made from VAM are ethylene-vinyl alcohol (EVOH) resins which are used as a gas barrier in multi-layered food and beverage packages, and as a barrier layer in automobile tanks.